How to make your own plant based soaps

/By: Gabe Garms

Homemade soap is both cost effective and typically of much higher quality than anything that you can buy in a store. Plus, it's relatively simple to make and only requires a few ingredients.There are primarily two types of soaps. One is made from plant based oils and the other made from rendered animal fat. In this post, I'll be going over how to make soap using plant based oils using the cold process method.

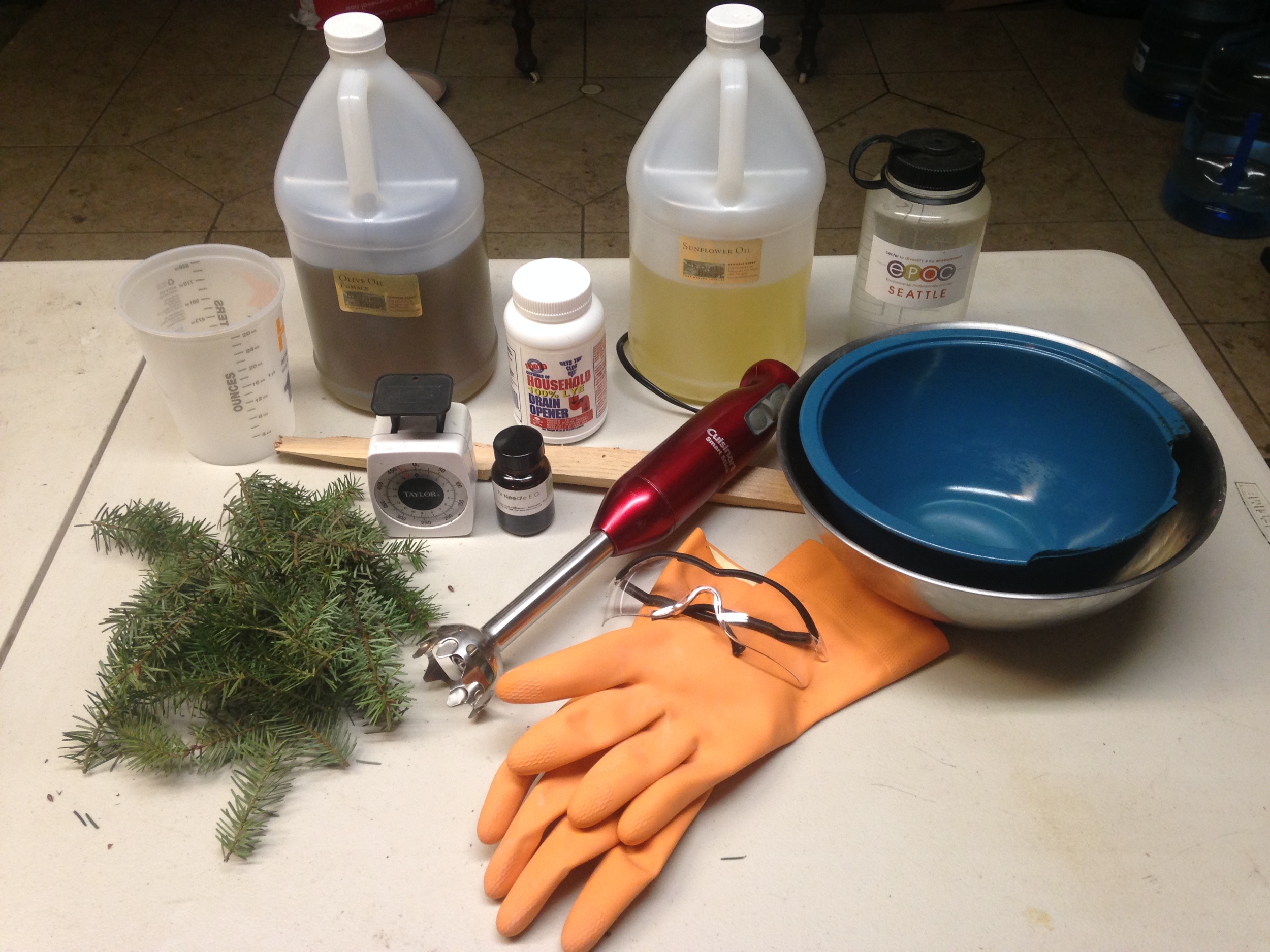

What you'll need:

-Scale that measures weight

-Plant based oils (Olive, sunflower, sesame, canola or any oil you have around the house). I typically always use at least 2 although it can work with just one

-2 mixing bowls (one cannot be made out of aluminum - the lye will eat away the aluminum)

-Lye (sodium hydroxide). Read how to make your own here.

-Distilled water

-Gloves and protective eyewear

-Stirring spoon or stick

-Essential oil of choice (in this recipe I'm using silver fir essential oil)

-Parchment paper

-Pan or molds (to form the soap)

-Something to wrap the pan with so heat won't escape (blankets or old clothing work best)

-Vinegar (Neutralizes the lye if it comes in contact with the skin during the soap making process)

-Stick blender (optional but recommended)

STEP 1: Measure out your oils by weight (it's very important that you don't measure by volume). The amounts of water and lye you'll have to use for your recipe will be completely dependent upon both what type and how much of each oil that you have available. In this recipe, I have 24 ounces of olive oil and 24 ounces of sunflower seed oil.

Before I begin measuring, I tare my scale to read 0 when my empty measurement container (a plastic cup in this case) is placed on top of it. The picture on the left is before I tared the scale (the cup weighs 1.5 ounces) and the one on the right is after the adjustment was made by turning the knob on the back of the scale.

STEP 2: Calculate how much lye you will need. Every type of oil has a specific SAP value associated with it. The SAP value reflects how much lye is required to saponify (or turn to soap) 1 ounce of that particular oil. There are quite a few websites which list the SAP values for different types of oils, but I've included a list below of some common ones that are readily available at most markets.

SAP Values (also included are soap characteristics associated with each type of oil):

Almond - .136 (lathering, conditioning)

Apricot Kernel - .137 (lathering, conditioning)

Avacado - .133 ((lathering, conditioning)

Borage - .133 (lathering, conditioning) .

Canola - .132 (lathering, conditioning)

Coconut - .191 (hardening, lathering)

Corn - .136 (lathering, conditioning)

Evening Primrose - .136 (lathering)

Hazelnut - .136 (lathering, conditioning)

Olive - .135 (lathering, conditioning)

Palm - .142 (hardening, lathering)

Sesame - .133 (lathering, conditioning)

Soybean - .136 (lathering, conditioning)

Sunflower - .136 (lathering, conditioning)

Walnut - .135 (lathering, conditioning)

NOTE: You can also use butters (shea, avacado, cocoa etc) in addition to oils. Butters are very moisturizing and make soap milder. Butters, as well as animal fats, all have specific SAP values and they can easily be found online.

Once you have the SAP value for your oil, simply multiply that value by how many ounces of oil that you have. In this recipe we are using 24 ounces of sunflower oil and 24 ounces of olive oil so our calculation looks like this:

Olive OIl: 24 x .135 = 3.24 ounces of lye

Sunflower Oil: 24 x .136 = 3.26 ounces of lye

3.24 ounces + 3.26 ounces = 6.5 total ounces of lye.

STEP 3: Superfat your recipe. What I mean by this is the 6.5 ounces of lye that we calculated in the last step will saponify all of oil in the mixture, leaving us with a dry and harsh bar. What superfatting does is ensure that some of the oil is left in the soap when it's finished, making it softer and less harsh. This is done by reducing the amount of lye that was calculated in the last step by between 5-10%. Most soap makers superfat their mixture by about 8%, and that's what we'll do it this particular recipe. So to superfat for this recipe, we take our lye amount and multiply it by .92 (or 8%).

6.5 ounces of lye x .92 = 5.98 ounces (I round to 6 for ease of measurement).

STEP 4: Calculate how much water you'll need. To do this, simply multiply your 6 ounces of lye (from Step 3) by 2.5.

6 ounces of lye x 2.5 = 15 ounces of distilled water.

So just to recap our measurements, here is what we are working with:

24 ounces of sunflower seed oil

24 ounces of olive oil

6 ounces of lye

15 ounces of distilled water

Now let's make some soap!

STEP 5: Get your vinegar and keep it by your side for this entire step (I'll tell you why at the end of this step). Pour the distilled water into a bowl (remember to avoid aluminum bowls) and take it outside. Once outside, put on your rubber gloves and goggles and slowly pour the lye crystals into the water while stirring with a spoon or stick (don't use aluminum for your spoon either).

When the water and lye are combined, the solution will heat up to a very high temperature and become very caustic (highly alkaline). If the solution does come in contact with the skin, it will start to turn the oils in your skin into soap. This is why we keep the vinegar by our side at all times since it will neutralize the burn caused by the lye water (vinegar is acidic). Keep stirring until the crystals are dissolved in the water. The solution will be cloudy at this point.

NOTE: It's very important to mention that you should never put the lye into the bowl first and then pour in the water. Please follow this step very carefully since it's the step where most people are injured in during the soap making process. Follow these exact steps and you'll be fine.

STEP 6: Set aside the lye water and let it cool down to around 100 degrees Fahrenheit. You can use a thermometer if you'd like to periodically take the temperature, but I found it to be very effective to just keep my eye on the solution and wait for it to become clear.

STEP 7: While your lye solution is cooling down, it's time to mix the oils together. If your oils are in liquid form, just pour them together into a bowl (see bowl on the right in the STEP 8 picture). However if you're using solidified oils, like coconut or palm, you'll want to melt them down first before you mix them with the other oils. If you are using solid oils, I would recommend using a double boiler to melt them down so that you don't burn them. Burnt oil makes bad soap, trust me.

STEP 8: When the lye water becomes clear (like the bowl on the left below), or reaches 100 degrees, then proceed to the next step.

STEP 9: Slowly pour your mixed oils into the bowl with the lye water and begin to stir with either a spoon or a stick blender. While a spoon can be effective, it takes significantly longer to mix the oils with the water than it would take with the stick blender (you can pick stick blenders up at thrift stores for under $10).

You'll want to continue stirring until you've achieved 'trace'. Trace is when you lift your stick or spoon out of the mixture and the trail of soap dripping from the spoon or blender sits on the surface of the mixture. See the picture below for an example.

STEP 10 (OPTIONAL): Now that your soap has been mixed, add your essential oil (for this batch I added about 1/4 ounce of silver fir essential oil - picture on left below) as well as any flowers, conifer needles or plant material of your choosing and mix into the soap. In this recipe, I'm adding needles from a Douglas fir tree (picture on right below). Not only do they smell great, they also help exfoliate the skin and are great additions to the soap. In other recipes that I've made, I've used rose petals, chamomile, calendula and lavender flowers. Be creative.

STEP 11: Line your baking pan with parchment paper and pour in your soap.

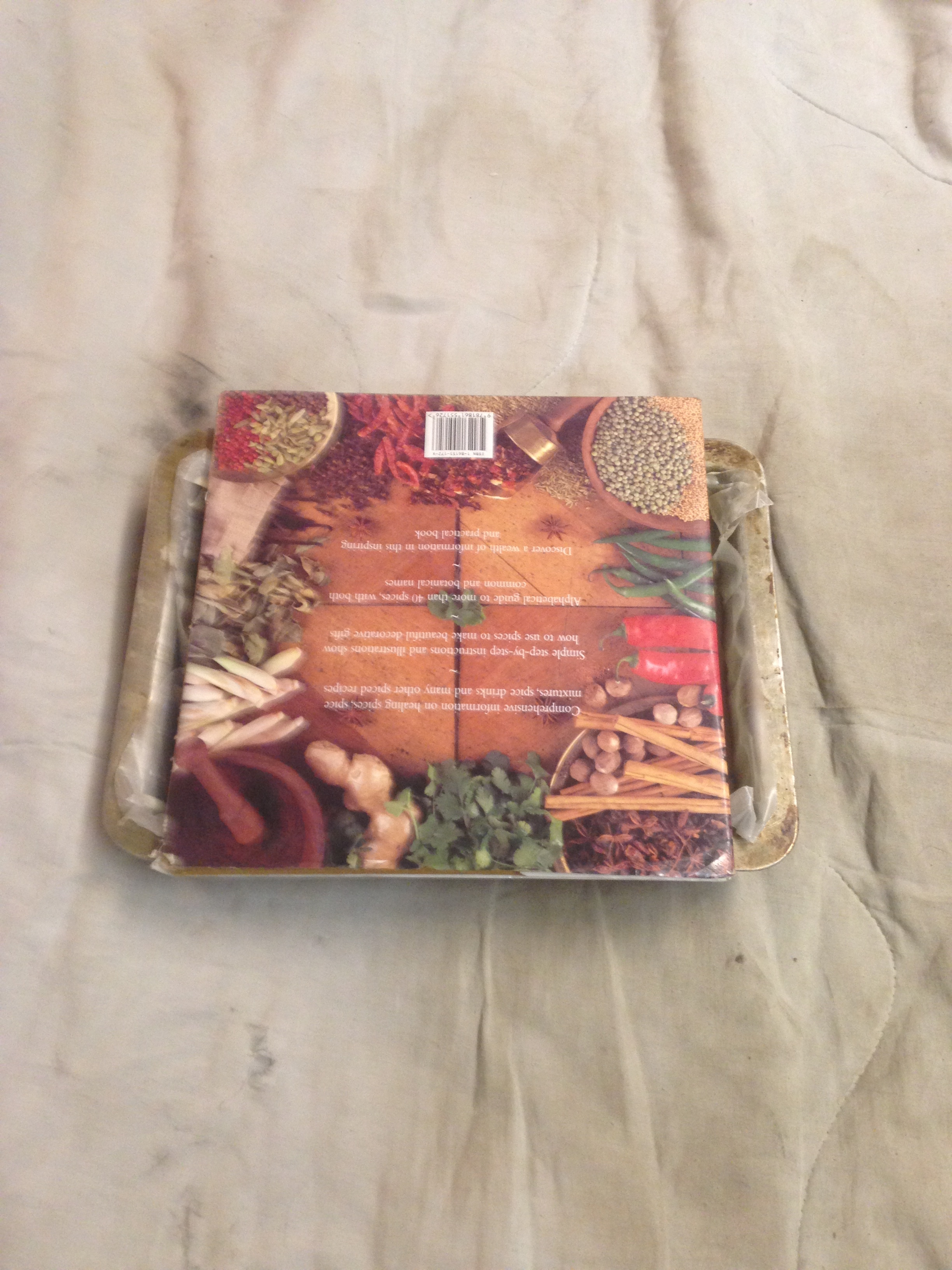

Once the soap has been poured, place a hard top over your baking pan (I used a hard cover book for this batch) and wrap the pan with a blanket or any material that can be fully wrapped around the pan (See pictures below).

The oils and the lye are still reacting with one another and generating heat, and you want to keep this heat trapped near the mixture (hence the blanket). Let the mixture sit for 24-48 hours.

STEP 12: After 24 hours, the soap will have solidified enough for you to cut it into bars. I typically let the soap harden for another 24 hours in the pan before I remove the bars and then air dry them for 4-6 weeks.

After the 4-6 weeks are up, the soap is ready to use! Experiment with different oils and fragrances and let me know if you come up with any great recipes.